How to Adjust Chainsaw Chain Tension Properly? Picture this: the sun is shining brightly overhead, casting dappled shadows on a sprawling backyard that’s desperately craving for a sprucing up. The once-overgrown bushes are now trimmed, the lawn is nicely mowed, and that old, unwieldy tree at the far end is just begging to be dressed down before it wreaks further havoc.

For such a task, you reach for your trusty chainsaw, the mighty sidekick that can tackle even the most intimidating yard work. But as you fire up the engine and guide the saw towards the tree, you suddenly notice that your chainsaw chain is not running as smoothly as it should. Your patience wears thin as the chain skips, chatters, and snags, making the job painfully slow and precarious.

Fret not, brave yard warrior! In this blog post, we will reveal the secrets of conquering the chainsaw chain tension and arm you with the knowledge to properly adjust it. Bid farewell to the frustration of a poorly performing chainsaw and stand tall, confident in your newfound skills as the master of your outdoor domain. Read on and take the first step towards an impeccably maintained garden utopia!

Table of Contents

1. Importance of Proper Chainsaw Chain Tension. How to Adjust Chainsaw Chain Tension Properly

The proper tension of a chainsaw chain is crucial for the overall performance and safety of the tool. A well-adjusted chain ensures efficient cutting and reduces the risk of accidents or damage to the chainsaw. Chains that are too tight can cause excessive strain on the drive sprocket and guide bar, leading to premature wear, while chains that are too loose may derail from the bar, potentially causing harm to the operator.

It is essential for chainsaw users to check the chain tension regularly, particularly during the first half hour of operation. Maintaining the correct chain tension not only ensures optimal performance but also helps prolong the lifespan of the chainsaw and enhance user safety. [1][2]

2. When to Check Chainsaw Chain Tension

It is essential to check your chainsaw chain tension frequently to ensure efficient operation and avoid unnecessary wear on your equipment. Ideally, you should evaluate the chain tension before you begin any cutting task and at regular intervals throughout the job. It is especially crucial to monitor the chain tension during the first half hour of use, as this is when the chain is most likely to become loose or unstable. If you notice slack in the chain, stop cutting immediately and allow the saw to cool down before readjusting the tension. Maintaining proper chain tension ultimately contributes to the longevity and effectiveness of your chainsaw. [3][4]

3. Locating Chain Tension Adjustment Points. How to Adjust Chainsaw Chain Tension Properly

Before adjusting the chainsaw chain tension, it is essential to locate the chain tension adjustment points on your chainsaw. These adjustment points may vary depending on the chainsaw model, so it’s crucial to refer to the user manual for specific instructions. Common locations for adjustment points include the side cover and the front of the chainsaw. Some models, like Oregon Intenz guide bars, have a built-in tensioning mechanism that allows you to tension the chain quickly and easily without requiring the bar tip to be held up during the process. By locating the correct chain tension adjustment points, you can ensure the proper tension for a safe and efficient chainsaw operation. [5][6]

4. Steps for Tensioning a Chainsaw Chain

To properly tension your chainsaw chain, follow these simple steps:

Step 1: Ensure the engine is off and the chain is cool. Loosen the nuts securing the side panel and guide bar, providing room for adjustments.

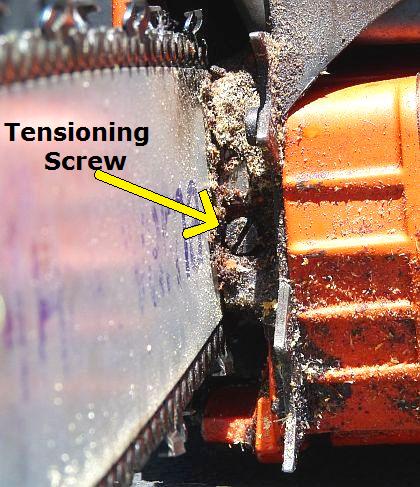

Step 2: Locate the tension adjustment screw on the side of the guide bar. Turn it clockwise to tighten or counterclockwise to loosen the chain.

Step 3: While holding the nose of the bar up, firmly tighten the mounting nuts back into place.

Step 4: Perform a snap test and check the chain tension by pulling it slightly away from the bar. The chain should be snug but able to move freely. Continue to check and adjust tension regularly during use for optimal performance and safety. [7][8]

5. Proper Chainsaw Maintenance Techniques

Proper chainsaw maintenance is crucial for the safety and efficiency of your equipment. Regularly performing certain tasks can greatly extend the life of your chainsaw and ensure it runs smoothly during operation. First, always make sure the engine is turned off before starting any maintenance work. Check the chain tension frequently, and adjust as needed to prevent it from becoming too loose or overly tight. Keep the guide bar clean and well-oiled to reduce friction and wear. Routinely inspect and clean the air filter, spark plug, and cooling fins to prevent overheating and ensure optimal performance. Lastly, always consult your chainsaw’s operator manual for specific maintenance instructions and recommendations. [9][10]

6. Ensuring Safety while Tensioning Chainsaw Chain

When adjusting the tension of your chainsaw chain, it is crucial to prioritize safety measures to prevent accidents and damage to your equipment. Firstly, ensure that the chainsaw is switched off, and the spark plug wire is disconnected to prevent any unintended start of the engine. Always wear thick safety gloves when handling the chain and blade. Protective goggles are also recommended to shield your eyes from debris during the tension adjustment process. Always refer to the manufacturer’s instructions for proper tensioning guidelines specific to your chainsaw model. Don’t forget to check and maintain the tension regularly to ensure the chainsaw operates smoothly and safely. [11][12]

7. Tips for Tensioning a Sprocket-nose Guide Bar

Proper tensioning of a sprocket-nose guide bar is vital for smooth and efficient chainsaw operation. Follow these seven tips to ensure optimal tension:

1. Turn off the engine and let the chain cool before adjusting tension.

2. Locate the chain tension adjustment points, typically found on the side cover or front of the chainsaw.

3. Loosen the bar nuts and hold the nose of the bar up while adjusting tension.

4. Turn the adjustment screw clockwise to tighten or counterclockwise to loosen the chain.

5. Ensure the drive links are fully seated in the guide bar groove, with light contact from the chain’s tie-straps.

6. Perform a “snap test” by pulling the chain down and releasing it, ensuring it snaps back into position.

7. Regularly check and adjust tension as needed, especially during the first half hour of chainsaw use. [13][14]

8. How to Use Intenz Guide Bars for Chainsaw Chain Tensioning

Intenz guide bars offer a convenient built-in tensioning mechanism, making chainsaw chain tensioning quick and effortless. Unlike regular guide bars, you do not need to hold the bar tip up while tensioning. First, loosen the bar nuts on the side of the chainsaw. Next, insert a screwdriver or a chainsaw scrench into the Intenz slot on the guide bar.

Rotate the tool clockwise to move the guide bar forward and achieve the proper chain tension. Perform a snap test to ensure the chain is tensioned correctly, then tighten the guide bar mounting nuts, starting with the back nut before moving on to the front. Lastly, with a gloved hand, pull the chainsaw chain along the top of the bar several times to check that it feels snug yet pulls freely. [15][16]

9. Over-tightening Risks in Chainsaw Chain Tensioning

It is crucial to be mindful of the dangers associated with over-tightening the chainsaw chain while attempting to maintain proper tension. Over-tightening can result in damage to the chain or even break it during operation, posing a potential hazard to the user. Moreover, over-tightened chains can prevent the chainsaw from turning the chain, generate excess heat, and even lead to a fire hazard.

Overheated chains and guide bars significantly reduce the lifespan of these components, and therefore, frequent tension checks should be performed throughout a job to ensure the correct balance between too tight and too loose. Always ensure you follow the manufacturer’s guidelines for proper chain tensioning. [17][18]

10. Importance of Regularly Checking Chainsaw Chain Tension.

Maintaining the proper tension on your chainsaw chain is critical for ensuring efficient operation and preventing accidents. Regularly checking and adjusting the chain tension helps prevent the chain from slipping off the guide bar or binding, which can result in poor cutting performance and potentially hazardous situations.

A poorly tensioned chain can also cause excessive wear and tear on your saw’s components, shortening its lifespan. Therefore, it is important to develop a routine of evaluating chain tension before beginning any cutting project and frequently during its course. By doing so, you will ensure that your chainsaw remains in optimal working condition, providing you with reliable and safe operation. [19][20]

FAQ: How to Adjust Chainsaw Chain Tension Properly

What is the correct tension on a chainsaw chain?

The correct tension for a chainsaw chain is achieved when it fits snugly against the guide bar but can still be manually rotated smoothly by hand. Avoid overtightening, ensuring there’s no sagging or excessive slack while allowing the chain to move freely along the bar.

Why does chainsaw chain keep coming loose?

A chainsaw chain might repeatedly come loose due to several reasons, including improper tensioning during use, heat causing the chain to expand and slacken, or a worn-out or stretched chain. Additionally, vibrations from the chainsaw’s operation can gradually loosen the chain if not adequately secured or if the fastening hardware isn’t properly tightened.

Why does my chainsaw jump when cutting?

A chainsaw jumping or bucking during cutting can occur due to various factors, including improper cutting techniques, a dull or improperly tensioned chain, encountering hard or uneven wood, or the chain getting pinched in the wood. Ensuring a sharp, properly tensioned chain, maintaining a stable cutting angle, and being mindful of the wood’s condition can help prevent this issue.

Why does my chainsaw chain stretch so much?

Chainsaw chains can appear to stretch due to wear caused by friction against the guide bar and sprocket, leading to a gradual increase in the chain’s length. Factors like prolonged use without proper maintenance, overheating, or using a dull chain can expedite this wear, giving the impression of stretching. Regular maintenance, including sharpening and proper tensioning, can help mitigate premature chain wear and elongation.

Conclusion: How to Adjust Chainsaw Chain Tension Properly

How to Adjust Chainsaw Chain Tension Properly? Mastering the art of adjusting chainsaw chain tension is a critical skill for every chainsaw operator. With the right tension, chainsaw performance is optimized, safety is enhanced, and the lifespan of both the chain and the saw is prolonged. By following these precise adjustment techniques, you’re empowered to ensure your chainsaw’s chain tension is always perfectly calibrated for efficient and safe cutting operations.

Read also: How Tight Should the Chain Be on a Chainsaw